Replacing an engine assembly in heavy machinery such as Komatsu excavators is a significant investment decision that directly impacts operational efficiency and costs. Faced with options ranging from brand-new engines to remanufactured units, buyers often struggle to balance budget constraints with performance and reliability requirements. Understanding the ins and outs of remanufactured Komatsu engine assemblies can empower you to make informed decisions that maximize value and minimize risk.

At Shandong Qianyu Construction Machinery Co., LTD., we offer a wide range of genuine new and remanufactured Komatsu engine assemblies tailored to meet various operational needs. This article explores what remanufactured engines are, their benefits, potential drawbacks, and how to select a trustworthy supplier for your excavator’s powertrain.

What Is a Remanufactured Engine Assembly?

Difference between remanufactured, refurbished, and new

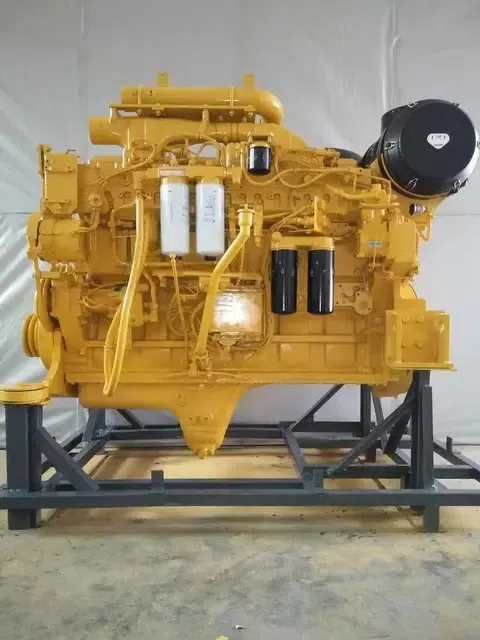

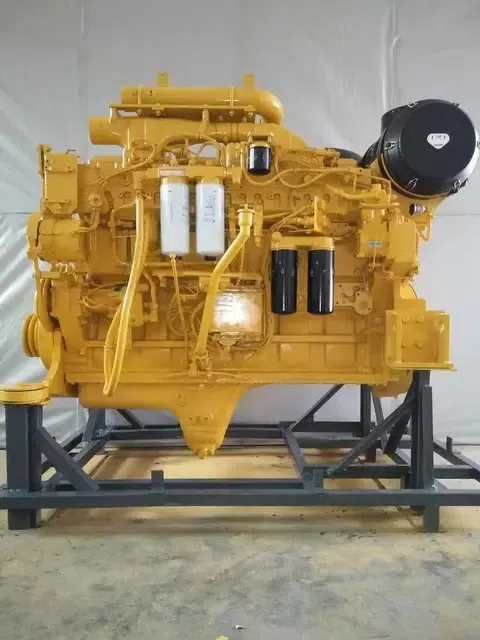

The terms remanufactured and refurbished are often used interchangeably, but they represent very different processes and product qualities. A remanufactured engine assembly is one that has been fully disassembled, thoroughly cleaned, meticulously inspected, and rebuilt to meet or exceed original factory standards. This process restores the engine’s performance to a near-new state, ensuring reliability and durability.

In contrast, refurbished engines typically undergo surface-level repairs or cosmetic fixes, which might include cleaning, repainting, and minor part replacement, but without comprehensive inspection or precision testing. These may offer short-term fixes but generally lack the long-term performance assurance of remanufactured units.

A new engine assembly is built entirely from new parts per OEM specifications, comes with the longest warranty, and guarantees the highest reliability but at the highest cost.

Understanding these distinctions helps in evaluating the value proposition of remanufactured engines compared to new or refurbished options.

Common processes involved in remanufacturing

Remanufacturing is a precise, multi-step procedure involving:

Complete disassembly: The engine is taken apart down to the block, allowing inspection of every internal component.

Cleaning: Parts undergo ultrasonic cleaning, chemical baths, and high-pressure washing to remove dirt, carbon deposits, and oil residues.

Inspection and measurement: Critical components such as cylinder walls, crankshafts, camshafts, pistons, valves, and bearings are measured using precision instruments. Worn or damaged parts are identified.

Replacement of worn parts: All components showing wear beyond tolerance—such as piston rings, bearings, gaskets, seals, and sometimes cylinder heads or injectors—are replaced with genuine OEM or OEM-equivalent parts.

Reconditioning: Components like cylinder heads and blocks may be machined to restore flatness and proper dimensions.

Reassembly: The engine is reassembled according to OEM torque and assembly specifications to ensure exact fit and function.

Testing: The remanufactured engine undergoes dyno testing to verify power output, fuel efficiency, and emissions compliance, simulating real operating conditions.

This rigorous approach guarantees that the remanufactured engine delivers performance and durability comparable to a new unit.

Pros of Choosing Remanufactured Komatsu Engine Assemblies

Cost savings without sacrificing performance

The most compelling reason to consider remanufactured Komatsu engine assemblies is the significant cost savings. Typically priced 30% to 50% lower than new engines, remanufactured units provide a financially accessible way to restore your excavator’s power while maintaining high performance standards.

For operators managing fleets or working within tight budgetary constraints, remanufactured engines offer a practical compromise. When properly remanufactured by OEM-compliant facilities, these engines deliver nearly identical horsepower, torque, and fuel efficiency as new assemblies.

Environmentally friendly choice

Remanufacturing is an environmentally responsible process. By reusing engine cores and components, remanufacturing reduces raw material consumption, energy use, and manufacturing waste. This significantly lowers the carbon footprint associated with engine production.

Companies prioritizing sustainability find remanufactured Komatsu engines align well with corporate social responsibility initiatives, helping to reduce environmental impact without compromising operational capability.

Faster turnaround time

New Komatsu engines, especially for larger models like the PC1250-8 or PC600-7, can face long lead times due to manufacturing and shipping logistics. Remanufactured engines are often available more quickly because they are rebuilt from existing engine cores and stocked parts.

This rapid availability can be crucial for minimizing costly equipment downtime, helping operations return to full productivity faster.

Cons and Potential Risks of Remanufactured Engines

Quality inconsistency with non-OEM remanufacturing

A major risk associated with remanufactured engines lies in quality variability. Not all remanufactured Komatsu engine assemblies adhere to strict OEM standards. Engines rebuilt by unqualified or third-party shops may use inferior parts, skip critical inspection steps, or fail to conduct proper testing.

Such engines often experience reduced reliability, higher failure rates, and increased maintenance requirements, negating initial cost savings. Selecting remanufactured engines from reputable, OEM-compliant suppliers is therefore critical to ensure consistent quality.

Shorter warranty coverage

Compared to new engines, remanufactured units usually come with shorter warranty periods, which may be limited to parts only or cover fewer operating hours. Some providers offer warranties ranging from six months to one year, while others might not offer any warranty.

This shorter warranty heightens the risk for owners, especially those operating in demanding environments, making warranty terms an important factor in purchase decisions.

Risk of mismatched or incompatible parts

Inexperienced remanufacturers may install incorrect or non-matching components such as fuel injectors, turbochargers, or sensors that are not designed for the specific Komatsu engine model. This mismatch can cause performance issues, engine management errors, or accelerated wear.

Verifying the authenticity of all components and supplier compliance with OEM specifications mitigates this risk.

How to Choose a Reliable Remanufactured Engine Provider

Verify OEM compliance and certifications

A trustworthy remanufacturer follows strict OEM procedures and uses genuine or OEM-equivalent parts. Look for providers with formal OEM authorization, certifications, and documented quality control processes.

At Shandong Qianyu Construction Machinery Co., LTD., every remanufactured Komatsu engine assembly complies with factory standards and is backed by quality assurance protocols.

Request comprehensive testing documentation

Ask suppliers for test reports demonstrating engine performance metrics such as horsepower, torque, emissions, and fuel consumption. These dynamometer results confirm that the engine meets or exceeds OEM performance benchmarks.

A transparent testing process reflects supplier confidence and product reliability.

Check customer reviews and industry reputation

Evaluate supplier credibility by researching customer feedback, case studies, and third-party reviews. Long-standing providers with proven track records in Komatsu engine remanufacturing demonstrate consistent quality and customer satisfaction.

Reputable suppliers also provide technical support and guidance during installation and operation, adding value beyond just the product.

Conclusion

A remanufactured Komatsu engine assembly presents a compelling option for excavator owners seeking to balance cost with reliable performance. When sourced from experienced, OEM-compliant providers, remanufactured engines offer near-new quality at a significantly lower price point, faster availability, and environmental benefits.

However, risks like quality inconsistency, shorter warranties, and potential component mismatches emphasize the importance of choosing your supplier carefully. At Shandong Qianyu Construction Machinery Co., LTD., we commit to delivering remanufactured Komatsu engine assemblies that meet rigorous quality standards, ensuring durability, efficiency, and peace of mind.

Contact us today to learn more about our remanufactured engine options and how they can keep your Komatsu excavators running strong without breaking your budget.