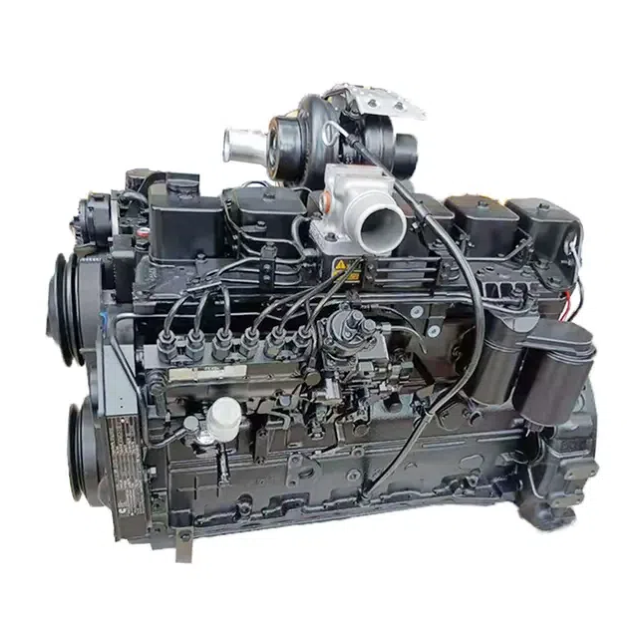

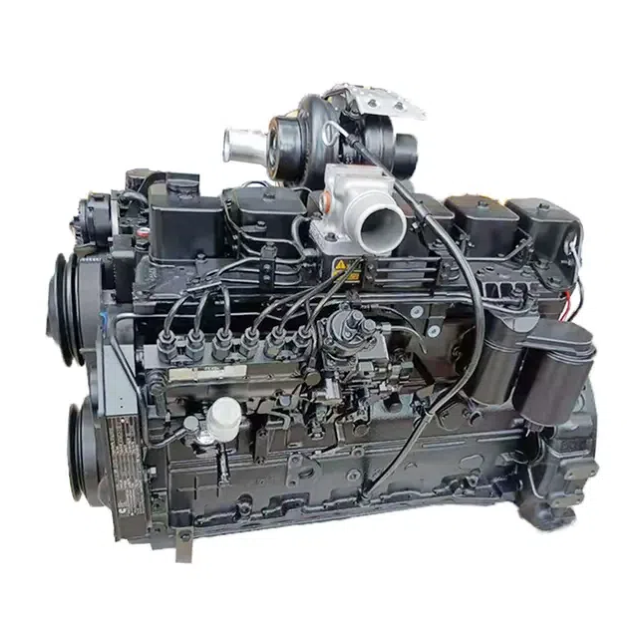

Komatsu excavators rely heavily on their engine assemblies to deliver consistent power and performance under demanding conditions. However, like any complex machinery, Komatsu engine assemblies can occasionally develop issues that affect starting, running, or overall efficiency. Understanding common problems and troubleshooting techniques helps equipment owners identify faults early and maintain optimal operation.

At Shandong Qianyu Construction Machinery Co., LTD., we support customers with high-quality Komatsu engine assemblies and expert advice to ensure your machines run reliably. This guide highlights frequent engine assembly issues, symptoms to watch for, and practical troubleshooting steps to help you keep your equipment in top condition.

Starting Issues

Weak battery or starter

One of the most common reasons a Komatsu engine assembly may fail to start is a weak or discharged battery. Excavator engines require substantial electrical current to power the starter motor and initiate combustion. Over time, batteries lose capacity due to age, frequent use, or extreme weather.

Starter motors can also wear out or suffer from faulty solenoids, resulting in slow cranking or no response when turning the ignition. Symptoms include clicking sounds without engine turnover or dim dashboard lights.

Troubleshooting tips:

Test battery voltage with a multimeter; a healthy battery should measure around 12.6 volts when off and maintain 13.7-14.7 volts when the engine runs.

Inspect battery terminals and cables for corrosion or loose connections; clean and tighten as needed.

Listen for starter clicks; if heard but no crank occurs, the starter motor or solenoid may need replacement.

Use a jump starter to check if a weak battery is causing the issue.

Fuel delivery problems

Fuel system faults can prevent proper combustion and cause starting difficulties. Blocked fuel filters, clogged injectors, or failing fuel pumps restrict fuel flow to the engine cylinders. Contaminated fuel with dirt or water also leads to ignition problems.

Signs include engine cranking but failing to start, sputtering, or rough idling immediately after startup.

Troubleshooting tips:

Replace fuel filters regularly following manufacturer recommendations.

Drain water separators and check for fuel contamination.

Inspect fuel lines and connections for leaks or damage.

If possible, test fuel pressure to ensure it meets Komatsu engine specifications.

ECU errors

Modern Komatsu engines use an Engine Control Unit (ECU) to monitor and regulate fuel injection, ignition timing, and other parameters. ECU faults or sensor malfunctions can cause starting failures or irregular engine behavior.

Warning lights on the dashboard or diagnostic codes may indicate ECU-related issues.

Troubleshooting tips:

Use a diagnostic scanner compatible with Komatsu engines to retrieve error codes.

Check wiring harnesses and connectors for damage or corrosion.

Reset the ECU by disconnecting the battery for several minutes.

Consult a technician if ECU faults persist.

Overheating or Smoke

Cooling system failure

Overheating is a critical issue for any engine assembly, potentially causing severe damage if not addressed promptly. Komatsu engine cooling systems rely on radiators, water pumps, thermostats, and coolant to dissipate heat generated by combustion and friction.

Failure of any cooling system component leads to elevated engine temperatures, which can cause warped heads, gasket failure, or engine seizure.

Troubleshooting tips:

Check coolant levels regularly and top up with recommended coolant types.

Inspect radiator fins and coolant hoses for leaks, blockages, or damage.

Test the thermostat to ensure it opens at the correct temperature.

Replace faulty water pumps or cooling fans promptly.

Leaking gaskets

A common symptom of gasket failure is white or blue smoke from the exhaust, indicating coolant or oil entering combustion chambers. Leaking head gaskets or intake manifold gaskets compromise engine cooling and lubrication, risking overheating and reduced power.

Troubleshooting tips:

Perform a compression test to identify cylinder leaks.

Check engine oil and coolant for cross-contamination (milky oil or coolant).

Monitor exhaust smoke color for clues on fluid leaks.

Replace damaged gaskets as soon as possible to prevent further damage.

Sensor malfunction

Temperature sensors monitor engine heat and relay data to the ECU and dashboard gauges. Faulty sensors can provide incorrect readings, causing inadequate cooling responses or false overheating warnings.

Troubleshooting tips:

Test temperature sensors with a multimeter or scan tool.

Replace defective sensors to ensure accurate temperature monitoring.

Verify wiring integrity and connections.

Power Loss or Performance Drops

Turbo failure

Komatsu engines often incorporate turbochargers to improve power output and fuel efficiency by forcing more air into combustion chambers. Turbocharger failure leads to reduced boost pressure, causing sluggish performance, black smoke, and increased fuel consumption.

Common causes of turbo failure include worn bearings, oil supply issues, or damaged turbine blades.

Troubleshooting tips:

Listen for unusual whining or grinding noises from the turbo area.

Inspect turbocharger for excessive shaft play or oil leaks.

Check oil supply lines for blockages or contamination.

Replace or rebuild turbos showing signs of failure.

Blocked fuel injector

Fuel injectors deliver precise amounts of fuel into cylinders for combustion. Clogged or leaking injectors cause uneven fuel distribution, misfires, and power loss.

Signs include rough idling, poor acceleration, and black smoke from the exhaust.

Troubleshooting tips:

Use fuel injector cleaner additives during refueling.

Replace faulty injectors after diagnostic testing.

Ensure fuel quality meets Komatsu standards.

Airflow restrictions

Clean airflow is essential for efficient combustion. Blocked or dirty air filters, intake hoses, or intercoolers reduce oxygen supply, lowering engine power and increasing emissions.

Troubleshooting tips:

Inspect and replace air filters regularly.

Check intake ducting for cracks, leaks, or obstructions.

Clean intercoolers to maintain optimal air cooling.

Unusual Noises or Vibrations

Loose mounts

Engine mounts secure the Komatsu engine assembly to the excavator frame, absorbing vibrations and shocks. Loose or damaged mounts cause excessive vibration, unusual noises, and can accelerate wear on other components.

Troubleshooting tips:

Visually inspect mounts for cracks or deterioration.

Tighten mounting bolts to specified torque values.

Replace mounts showing excessive wear.

Engine imbalance

Imbalances from bent crankshafts, worn pistons, or damaged connecting rods cause knocking noises, vibrations, and reduced engine smoothness.

Troubleshooting tips:

Listen for knocking or rattling sounds at various RPMs.

Schedule professional engine diagnostics if imbalance is suspected.

Address imbalance issues early to avoid catastrophic failure.

Piston or ring wear

Worn pistons or rings reduce compression, causing power loss, increased oil consumption, and smoke emissions.

Troubleshooting tips:

Conduct a compression or leak-down test.

Monitor oil consumption rates.

Replace piston rings or overhaul engine if wear is significant.

When to Call a Technician

Warning signs that need expert help

Certain symptoms require prompt professional attention, including:

Persistent starting failures after basic troubleshooting.

Severe overheating with visible smoke or steam.

Loud knocking or grinding noises from the engine.

Sudden loss of power or fuel inefficiency.

Warning lights or fault codes unresolvable with simple resets.

Delaying repairs increases the risk of extensive damage and higher repair costs.

Costs of delay in repair

Ignoring early symptoms can lead to catastrophic engine failure, resulting in:

Extended downtime and lost productivity.

Higher repair or replacement expenses.

Potential damage to other excavator systems.

Safety hazards for operators and nearby workers.

Regular maintenance combined with timely troubleshooting preserves engine health and operational safety.

Conclusion

Proactive troubleshooting of your Komatsu engine assembly plays a vital role in maintaining excavator performance and minimizing costly repairs. By understanding common problems such as starting difficulties, overheating, power loss, and unusual noises, operators can detect issues early and apply effective solutions or seek expert assistance.

At Shandong Qianyu Construction Machinery Co., LTD., we provide reliable Komatsu engine assemblies and technical support to keep your machinery running efficiently. Investing time in early problem detection not only saves repair costs but also extends the lifespan of your equipment.

Contact us to explore our quality Komatsu engine assemblies and get professional advice on maintenance and troubleshooting for your excavators.