Ever wondered how a small device like a turbocharger can transform engine performance? This marvel of engineering boosts power by forcing more air into the combustion chamber. Turbochargers have evolved significantly since their inception, becoming a staple in the automotive industry for enhancing efficiency and horsepower. In this post, you'll learn how turbochargers work, their impact on horsepower, and why they're favored by car enthusiasts worldwide.

How Turbochargers Work

Basic Mechanics of a Turbocharger

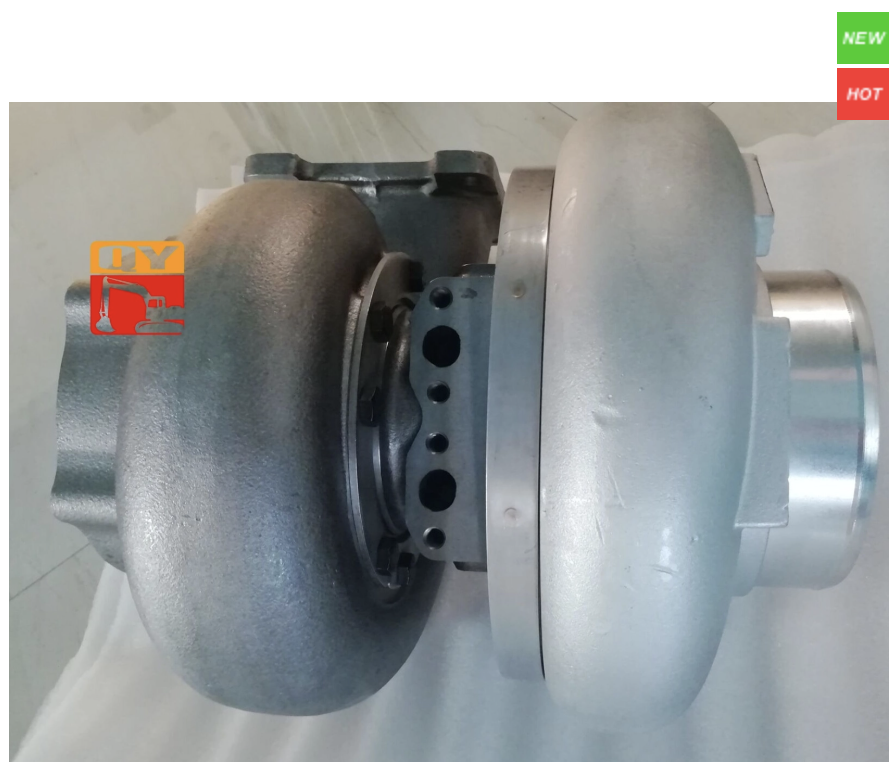

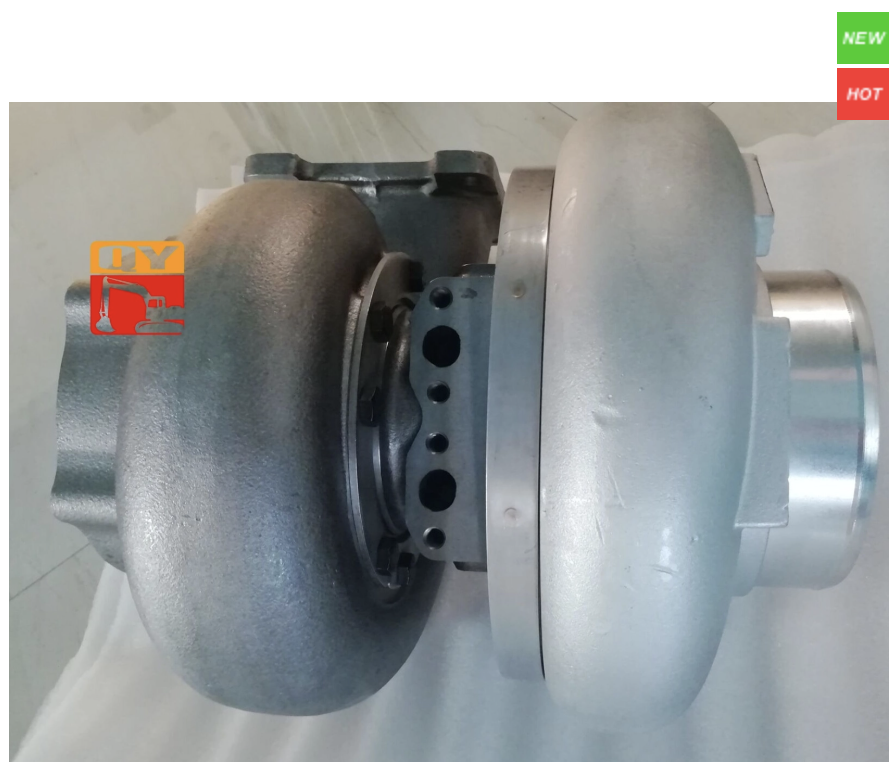

A turbocharger is a device that boosts an engine's power by forcing more air into the combustion chamber. It uses a turbine and a compressor connected by a shaft. The turbine spins because of exhaust gases leaving the engine. This spin drives the compressor, which draws in and compresses air before sending it into the engine. More air means more oxygen, allowing the engine to burn more fuel and produce more power.

The Role of Exhaust Gases

Exhaust gases play a crucial role in turbocharger operation. Instead of letting these gases escape unused, the turbocharger harnesses their energy to spin the turbine. This process recycles energy that would otherwise be wasted. The faster the engine runs, the more exhaust gases it produces, which in turn spins the turbine faster and compresses more air. This creates a cycle that increases engine efficiency and power output.

Components of a Turbocharger System

A turbocharger system includes several key parts:

Turbine: Captures energy from exhaust gases.

Compressor: Compresses incoming air to increase oxygen supply.

Shaft: Connects turbine and compressor, transferring rotational energy.

Wastegate: Controls exhaust flow to prevent over-boosting.

Intercooler: Cools compressed air before it enters the engine, increasing density and power.

Oil and coolant lines: Keep the turbocharger lubricated and cool.

Each component works together to ensure the turbocharger operates efficiently and reliably, boosting horsepower without significantly increasing engine size.

Tip: When considering turbocharger upgrades, ensure your engine’s exhaust system and cooling components can handle the increased flow and heat for optimal performance and durability.

Impact of Turbochargers on Horsepower

How Turbochargers Increase Horsepower

Turbochargers boost horsepower by forcing more air into the engine's combustion chamber. More air means more oxygen, which allows the engine to burn more fuel. This combustion creates more power than a naturally aspirated engine of the same size. Essentially, the turbo acts like a high-powered air pump, compressing the intake air and increasing the engine’s volumetric efficiency.

When the turbo spins, driven by exhaust gases, it compresses the incoming air. This compressed air is denser, containing more oxygen molecules per volume. The engine management system adjusts fuel delivery to match this increased oxygen, resulting in a more powerful combustion stroke and higher horsepower output.

Factors Influencing the Horsepower Gain

The amount of horsepower a turbocharger adds depends on several factors:

Turbo Size and Design: Larger turbos can push more air, leading to bigger horsepower gains, but might cause turbo lag. Smaller turbos spool faster but offer less top-end power.

Engine Displacement: Bigger engines can handle more boost and fuel, producing more power gains.

Boost Pressure: Higher boost pressures increase horsepower but require stronger engine components to handle the stress.

Air Intake and Exhaust Efficiency: Upgraded intercoolers, intake manifolds, and exhaust systems help maximize the turbo’s effectiveness.

Fuel Delivery and Engine Tuning: Proper tuning ensures the engine uses the extra air efficiently without knocking or damaging components.

Supporting Modifications: Strengthening pistons, rods, and valves allows the engine to safely handle increased power.

Typically, a well-matched turbocharger can add between 30% to over 50% more horsepower compared to a naturally aspirated engine. For example, a 200-horsepower engine might see gains of 60 to 100 horsepower after turbocharging, depending on the setup.

Comparing Turbochargers with Superchargers

Both turbochargers and superchargers increase horsepower by forcing more air into the engine, but they differ in operation:

Power Source: Turbos use exhaust gases, recycling energy that would otherwise be wasted. Superchargers are mechanically driven by the engine’s crankshaft, consuming some engine power to operate.

Efficiency: Turbos tend to be more efficient since they use exhaust energy, providing better fuel economy and higher peak power.

Turbo Lag vs. Immediate Response: Turbos may experience lag before spooling up, causing delayed power delivery. Superchargers provide instant boost, improving throttle response.

Heat Generation: Turbos generate more heat due to exhaust gas energy, requiring intercoolers. Superchargers produce less heat but still increase intake air temperature.

Complexity and Cost: Turbo systems are generally more complex and can be costlier to install and maintain.

Choosing between the two depends on the desired power characteristics, engine design, and application. Turbochargers are popular for their efficiency and high power potential, while superchargers excel in providing immediate throttle response.

Tip: When upgrading horsepower with a turbocharger, ensure your engine’s fuel system, cooling, and internal components are upgraded to handle increased boost and prevent damage.

Types of Turbochargers

Turbochargers come in different types, each designed to meet specific performance needs and engine characteristics. Understanding these types helps in selecting the right turbo for your vehicle and horsepower goals.

Single Turbo

A single turbocharger uses one turbine and compressor to boost engine power. It is the simplest and most common type. Single turbos are popular for their straightforward design, ease of installation, and cost-effectiveness. They can provide significant horsepower gains, especially when matched properly to engine size and intended use.

Advantages: Simple setup, lower cost, reliable.

Best for: Daily drivers, moderate performance upgrades, smaller engines.

However, single turbos may suffer from turbo lag, where power delivery is delayed as the turbo spools up.

Twin-Turbo

Twin-turbo systems use two turbochargers instead of one. These can be arranged in two main ways:

Parallel Twin-Turbo: Both turbos operate simultaneously, each feeding half the engine’s cylinders. This setup balances power delivery and reduces lag.

Sequential Twin-Turbo: One small turbo works at low RPMs for quick response, while a larger turbo kicks in at higher RPMs for more power.

Twin turbos offer better throttle response and more horsepower across a wider RPM range than single turbos.

Advantages: Reduced lag, improved power delivery, higher peak horsepower.

Best for: High-performance cars, larger engines, racing applications.

The complexity and cost are higher, and installation requires more space and tuning.

Variable Geometry Turbochargers (VGT)

Variable Geometry Turbochargers adjust the turbine’s vane angles to optimize exhaust flow. This allows the turbo to perform efficiently at both low and high engine speeds.

Advantages: Minimal turbo lag, improved fuel efficiency, broad power band.

Best for: Modern diesel engines, performance vehicles needing smooth power delivery.

VGTs are more complex and expensive but offer excellent drivability and efficiency.

Tip: When choosing a turbocharger type, consider your engine size, desired horsepower increase, and driving style to balance performance gains and responsiveness effectively.

Benefits of Using Turbochargers

Improved Engine Efficiency

Turbochargers improve engine efficiency by making better use of exhaust gases. Instead of wasting these gases, a turbo captures their energy to compress incoming air. This means more oxygen enters the combustion chamber, allowing the engine to burn fuel more completely. As a result, the engine produces more power without increasing its size or fuel consumption proportionally. This improved efficiency can lead to better fuel economy compared to naturally aspirated engines delivering the same power.

Additionally, turbochargers help smaller engines deliver power comparable to larger engines. This downsizing reduces overall vehicle weight and friction losses, further enhancing efficiency. Modern turbocharged engines often include intercoolers, which cool the compressed air, increasing its density and combustion quality. Together, these factors contribute to a more efficient engine operation.

Enhanced Performance

Turbochargers significantly boost engine performance by increasing horsepower and torque. By forcing more air into the engine, they enable it to burn more fuel, creating stronger combustion strokes. This results in quicker acceleration, higher top speeds, and improved towing or hauling capabilities.

Performance gains depend on turbo size, boost pressure, and engine tuning. A well-matched turbo setup can add 30% to over 50% more horsepower. For example, a 200-horsepower engine might gain 60 to 100 horsepower after turbocharging. Turbochargers also improve torque, especially at mid to high RPMs, making the engine feel more responsive and powerful during everyday driving.

Moreover, turbochargers allow performance tuning without major engine modifications. Enthusiasts can upgrade turbos, intercoolers, or engine management systems to extract even more power safely and reliably.

Environmental Advantages

Turbochargers offer environmental benefits by enabling smaller, more efficient engines to produce the power of larger ones. This downsizing reduces fuel consumption and lowers CO2 emissions. Since turbos use exhaust gases to operate, they recycle energy that would otherwise be wasted, improving overall engine efficiency.

Additionally, turbocharged engines can meet stricter emission standards by optimizing combustion. The increased air supply allows for cleaner burning of fuel, reducing harmful pollutants like carbon monoxide and unburned hydrocarbons.

Some modern turbo systems also integrate with advanced technologies such as variable geometry turbochargers (VGTs) or electric assist turbos, which help minimize turbo lag and improve efficiency further. These innovations support greener vehicles without sacrificing performance.

Tip: To maximize benefits, ensure your engine’s cooling and fuel systems are upgraded alongside the turbocharger to handle increased pressures and temperatures safely.

Challenges and Considerations

Potential Downsides of Turbochargers

Turbochargers offer impressive horsepower gains, but they come with some drawbacks. First, they add complexity to the engine system. This complexity can lead to higher repair costs if something goes wrong. Turbochargers also generate significant heat, which places extra stress on engine components. Without proper cooling, this heat can reduce engine life.

Another concern is the increased pressure inside the engine. Higher boost pressures mean the engine must handle more stress, requiring stronger components. If the engine isn’t built for this, it risks damage like blown head gaskets or piston failure. Also, turbocharged engines often require premium fuel to prevent knocking, which adds to operating costs.

Lastly, turbochargers can cause turbo lag—a delay between pressing the accelerator and the turbo delivering boost. This lag affects throttle response and can make driving feel less smooth, especially at low RPMs.

Maintenance and Longevity

Maintaining a turbocharged engine requires extra attention. Turbochargers spin at very high speeds and operate under extreme temperatures, so oil quality and flow are critical. Regular oil changes using manufacturer-recommended synthetic oils help protect the turbo’s bearings.

It’s also important to let the engine idle for a minute or two after hard driving. This cooldown period allows the turbo to slow down gradually and prevents oil coking, which can clog oil passages and cause premature turbo failure.

Inspecting and replacing air filters regularly is key, too. Clean air prevents debris from damaging the compressor wheel. Additionally, checking for leaks in the intake and exhaust system ensures the turbo operates efficiently.

Proper maintenance can extend turbocharger life to 100,000 miles or more, but neglect can shorten it drastically.

Turbo Lag and How to Minimize It

Turbo lag occurs because the turbo relies on exhaust gas flow to spool up and build boost. At low engine speeds, exhaust flow is limited, so the turbo spins slowly, delaying power delivery.

Several strategies help reduce lag:

Smaller Turbochargers: They spool faster due to lower rotational inertia but may limit top-end power.

Twin-Turbo Systems: Using two turbos, one small for low RPM and one large for high RPM, balances quick response and peak power.

Variable Geometry Turbochargers (VGT): Adjust turbine vanes to optimize exhaust flow, improving spool speed across RPM range.

Electric Assist Turbos: Use electric motors to spin the turbo instantly before exhaust gases take over.

Improved Engine Tuning: Fine-tuning fuel and ignition timing helps maximize boost response.

Upgraded Exhaust Systems: Reducing backpressure allows exhaust gases to flow more freely, helping the turbo spool faster.

While some lag is inevitable, these methods significantly improve throttle response and driving feel.

Tip: Always pair turbocharger upgrades with proper engine strengthening and cooling improvements to avoid damage and maintain reliability over time.

Turbocharger Installation and Cost

Installation Process Overview

Installing a turbocharger involves several precise steps to ensure proper function and reliability. First, the old exhaust manifold or intake components may need removal to make room for the turbo. Next, the turbocharger is mounted to the exhaust manifold or a dedicated turbo flange. Proper alignment is critical to avoid leaks or stress on the turbo housing.

Then, oil and coolant lines must be connected. These lines lubricate and cool the turbo during operation, preventing damage from heat and friction. The intake piping is routed from the turbo compressor outlet to the engine’s intake manifold, often passing through an intercooler to cool the compressed air.

The exhaust side includes a wastegate or blow-off valve installation to regulate boost pressure and prevent over-boosting. Finally, sensors and engine management components are integrated or recalibrated to handle the turbo’s increased airflow and pressure.

The entire installation requires mechanical expertise and careful tuning. Improper installation can lead to turbo failure, engine damage, or poor performance.

Cost Factors to Consider

Turbocharger installation costs vary widely depending on several factors:

Turbocharger Type and Quality: High-performance or brand-name turbos cost more but offer better durability and power gains.

Vehicle Make and Model: Some engines require custom parts or complex installation, increasing labor costs.

Supporting Upgrades: Often, fuel system upgrades, stronger engine internals, or improved cooling systems are needed, adding to expenses.

Labor Rates: Professional installation can be costly, especially in regions with high labor costs.

Tuning and Calibration: Proper engine tuning after installation is essential for performance and reliability, incurring additional costs.

On average, a turbocharger kit may cost between $1,000 and $3,000, while installation labor can range from $500 to $2,000 or more. Total costs often reach $2,000 to $5,000 depending on the vehicle and desired performance level.

DIY vs Professional Installation

While some experienced enthusiasts attempt DIY turbo installations, professional installation is generally recommended. Turbo systems are complex, requiring precise mechanical work and engine tuning.

DIY risks include:

Incorrect mounting leading to leaks or damage.

Improper oil or coolant line routing causing turbo failure.

Engine damage from inadequate tuning or boost control.

Voiding warranties or insurance coverage.

Professional installers bring specialized tools, knowledge, and experience. They ensure correct installation, perform necessary upgrades, and calibrate engine management for optimal power and reliability.

For those with mechanical skills and proper tools, DIY may save money but demands thorough research and patience. Otherwise, professional installation is safer and more reliable.

Tip: Always budget for professional engine tuning and supporting upgrades when planning a turbocharger installation to protect your engine and maximize horsepower gains.

Conclusion

Turbochargers significantly enhance horsepower by forcing more air into an engine, boosting efficiency and performance. Future trends in turbocharging technology promise even greater advancements in power and fuel economy. Shandong Qianyu Construction Machinery Co., LTD. offers innovative turbocharger solutions, providing substantial value through increased engine power and efficiency. These advancements allow engines to perform at higher levels without requiring larger displacements, making turbochargers a valuable addition for those seeking enhanced performance and efficiency.

FAQ

Q: What is a turbocharger?

A: A turbocharger is a device that increases an engine's horsepower by forcing more air into the combustion chamber using exhaust gases to spin a turbine and compressor.

Q: How does a turbocharger increase horsepower?

A: Turbochargers increase horsepower by compressing air, allowing more oxygen into the engine, which enhances fuel combustion and power output.

Q: Why might a turbocharger be preferred over a supercharger?

A: Turbochargers are often preferred for their efficiency, as they use exhaust gases to boost power without directly consuming engine power, unlike superchargers.

Q: How much does it cost to install a turbocharger?

A: Turbocharger installation costs vary but typically range from $2,000 to $5,000, including parts, labor, and necessary engine tuning.

Q: What are the benefits of using a turbocharger?

A: Turbochargers improve engine efficiency, enhance performance, and offer environmental advantages by enabling smaller engines to produce more power.