Have you ever faced downtime due to an incorrect hydraulic cylinderreplacement? Ensuring the right measurements is crucial to avoiding costly mistakes.

Hydraulic cylinders power essential machinery, and accurate measurements are key for optimal performance. In this guide, we’ll show you how to measure a hydraulic cylinder, from understanding its components to ensuring a perfect fit. Get ready to learn the steps to measure and replace your hydraulic cylinder with confidence.

Understanding Hydraulic cylinders

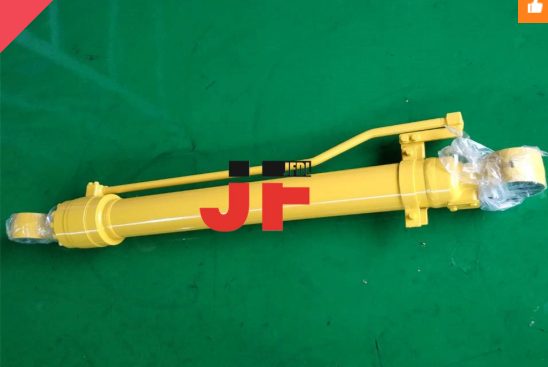

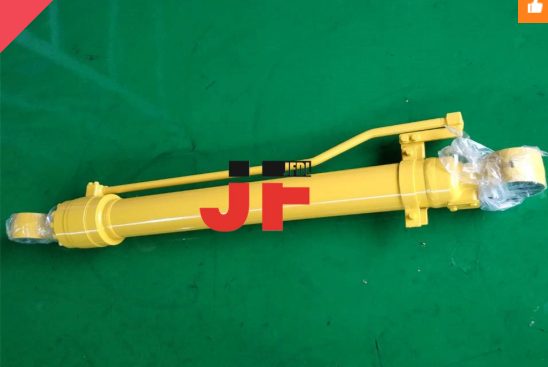

Hydraulic cylinders are the heart of many heavy-duty machines, powering everything from excavators to forklifts. To ensure these machines operate smoothly and efficiently, it’s essential to measure hydraulic cylinders accurately when they need replacement or maintenance.

Accurate measurements are critical to avoid operational issues and prevent downtime. When your hydraulic cylinder fails, incorrect replacement sizes can lead to poor performance or even further damage. Knowing how to measure your hydraulic cylinder can save both time and money. Whether you're replacing a faulty cylinder, performing routine maintenance, or planning an upgrade, this guide will help you navigate the measurement process with ease.

When to Measure Your Hydraulic Cylinder

You should measure your hydraulic cylinder during:

Repair or Replacement: When your cylinder is malfunctioning or damaged.

Routine Maintenance: To check wear and tear or plan for replacements.

Upgrades: When you need a cylinder that offers better performance.

Essential Tools for Measuring a Hydraulic Cylinder

Tape Measure

A tape measure is essential for capturing basic dimensions like the retracted and extended lengths of the hydraulic cylinder. Make sure the tape is accurate, and measure the lengths from pin center to pin center to ensure precision.

Calipers

For high-precision measurements, especially of the rod diameter and bore diameter, calipers are a must. They provide the accuracy needed to measure components like the rod thickness and internal cylinder diameter.

Notebook & Pen

Keep a notebook to record all your measurements as you go. This helps prevent errors and serves as a valuable reference when troubleshooting or ordering replacement parts.

Safety Equipment

Remember to power down the equipment and release the hydraulic system's pressure before measuring. Safety glasses and steel-toed boots are essential for protection while working with heavy machinery.

Always double-check your measurements to avoid errors, as incorrect dimensions can cause installation problems or mechanical failure.

Key Hydraulic Cylinder Components to Measure

Bore Diameter (Piston Diameter)

The bore diameter refers to the inside diameter of the cylinder, or the size of the barrel through which the piston moves. It’s the most crucial dimension as it directly impacts the force generated by the cylinder.

Measurement Methods

If you're replacing a cylinder, ensure the bore diameter is the same to handle the workload properly.

Rod Diameter

The rod diameter refers to the thickness of the piston rod that extends out of the cylinder. This rod transmits force to the machine, so a properly sized rod is vital for preventing bending or failure under pressure.

Measurement Methods

Use calipers to carefully measure the rod's outer diameter. This measurement is critical for ensuring the rod can handle the forces applied during operation. Precision is key, as even small discrepancies can lead to issues such as rod bending, misalignment, or improper fitting, compromising the hydraulic cylinder's performance and longevity.

Retracted and Extended Length

The retracted length is the cylinder’s length when fully closed, and the extended length is the full extension of the rod. These dimensions are critical to ensuring your new cylinder fits into your machinery.

How to Measure:

Retracted Length: Measure from the pin center at the rod’s mounting point to the pin center at the cylinder’s base end.

Extended Length: Measure from the same points, but when the rod is fully extended.

Tip: Accurately measuring these lengths ensures that the replacement cylinder fits perfectly, preventing misalignment during operation.

Stroke Length

The stroke length is the total working distance the piston can travel. It determines the range of motion available to your machine.

How to Calculate:

The stroke is calculated by subtracting the retracted length from the extended length.

Example:

If the extended length is 20 inches and the retracted length is 10 inches, then the stroke length is 20" - 10" = 10 inches.

Additional Considerations for a Perfect Fit

Mounting Styles

The mounting style determines how the cylinder is attached to your machinery. Common types include:

Clevis Mount: A U-shaped bracket with pin holes.

Flange Mount: A flat surface with bolt holes.

Trunnion Mount: Cylinders mounted on both ends with strong support.

Each style requires its own set of measurements to ensure the new cylinder will fit correctly.

How to Measure:

Measure the pin-to-pin distance for clevis mounts, and ensure the bolt pattern aligns for flange mounts. Trunnion mounts may require specific hole diameter measurements.

Port Sizes and Thread Types

The port size and thread type determine how hydraulic hoses connect to the cylinder. Common thread types include SAE, NPT, and JIC, and each has different fitting requirements.

How to Measure:

If the ports don't match, you can use an adapter to ensure proper hose connections.

Working Pressure

Hydraulic cylinders operate under varying pressure levels, depending on the machine’s requirements. It’s crucial to know the working pressure of your system to choose the right replacement cylinder.

Why It Matters:

If the replacement cylinder has a lower pressure rating, it could lead to failure during operation. Ensure the pressure rating of the new cylinder matches or exceeds the requirements.

| Measurement Component | Description | How to Measure |

| Bore Diameter | Inside diameter of the cylinder barrel, critical for strength. | Use calipers to measure the internal diameter or subtract wall thickness. |

| Rod Diameter | Thickness of the piston rod, ensuring stability. | Measure with calipers for precision and check the rod's ability to withstand pressure. |

| Retracted Length | Cylinder length when fully closed. | Measure from pin center at the rod's mounting point to the base end when retracted. |

| Extended Length | Cylinder length when fully extended. | Measure from pin center at the rod's mounting point to the base end when extended. |

| Stroke Length | The total distance the piston can travel. | Calculate by subtracting retracted length from extended length. |

| Mounting Style | Connection method to machinery. | Measure pin-to-pin for clevis mounts, and bolt pattern for flange mounts. |

| Port Sizes and Threads | Ensures compatibility with hydraulic hoses. | Measure port size and use a thread gauge to determine thread type. |

| Working Pressure | The pressure at which the hydraulic cylinder operates. | Match the pressure rating with the system's requirements to ensure safety. |

How to Measure Hydraulic Cylinder Components (Step-by-Step)

Step 1: Bore Diameter

Method: Measure the internal diameter of the barrel if disassembled, or the external diameter minus wall thickness if assembled.

Why: The bore diameter dictates the force the cylinder can generate.

Step 2: Rod Diameter

Step 3: Retracted and Extended Lengths

Step 4: Stroke Calculation

Method: Subtract the retracted length from the extended length.

Why: The stroke length determines the movement range of the cylinder, which is vital for the operation.

Understanding Mounting and Hose Connections

Mounting Styles and Dimensions

Measuring Hose Ports

Ensure mounting and port measurements are exact to prevent installation issues.

When to Seek Professional Help

Signs of Major Damage

If your hydraulic cylinder is severely damaged or bent, attempting to replace it yourself may lead to further issues. In such cases, it’s best to consult with an expert to ensure the right fit and prevent complications.

Why Expert Advice May Be Necessary

Some cylinders may have complex features or require specific measurements that are difficult to assess without the proper expertise. Professionals can help you accurately assess the damage and ensure you get the correct replacement.

Conclusion

Measuring a hydraulic cylinder is essential for ensuring a proper fit during replacement or repair. Accurate measurements of the bore diameter, rod diameter, retracted and extended lengths, and stroke can prevent costly mistakes and downtime.

For the best results, always double-check your measurements and consult with a professional if needed. At Qianyu, our hydraulic cylinders are designed to provide optimal performance and long-lasting durability, ensuring your machinery operates smoothly. Trust Qianyu for reliable, high-quality hydraulic solutions.

FAQ

Q: How do I measure a hydraulic cylinder's bore diameter?

A: To measure the bore diameter of a hydraulic cylinder, use a caliper to measure the internal diameter of the cylinder barrel or subtract the wall thickness from the external diameter if the cylinder is assembled.

Q: Why is it important to measure the rod diameter of a hydraulic cylinder?

A: The rod diameter affects the strength and stability of the hydraulic cylinder. Using precise calipers ensures the rod can withstand the operational forces without bending or breaking.

Q: What is the stroke length of a hydraulic cylinder?

A: The stroke length is the total distance the piston moves, calculated by subtracting the retracted length from the extended length of the cylinder.

Q: How do I measure the retracted and extended lengths of a hydraulic cylinder?

A: Measure from the center of the pinhole at the rod’s mounting point to the center of the pinhole at the cylinder’s base end when the rod is fully retracted and extended.

Q: When should I seek professional help in measuring a hydraulic cylinder?

A: If the cylinder is severely damaged or has complex features, it’s best to consult a professional to avoid mismeasurement and ensure proper functionality.